How our bag project process works.

1

Material Arrangement

We order from the moment of order confirmation to ensure that our raw materials are fresh and we have the resources of a wide range of raw material suppliers to ensure that you can get the materials you want. If you have a designated material factory, please give us their contact information. We can import materials as required!

2

Rotogravure Printing / Digital Printing

With our rotogravure printing press, the production of colors is highly accurate and we can print up to 17 colors. To meet the high demand, we are also capable of digital printing with 24 color max(up to 760 mm wide originals). with superior printing capabilities that allow us to adapt to various printing needs.

3

Lamination

Lamination gives a product new character by layering individual sheets of film onto it. This is the most important process that forms the foundation of product creation and makes or breaks product quality. In addition to dry lamination, we also offer PE extrusion lamination. Contribute to a greener future,user safety and reduced environmental impact, we use solvent free adhesives!

4

Pouchmaking

Six pouchmaking machines enable us to produce all kinds of types including Stand up Pouch, Flat Bottom Bag, Spout Pouch, Side Gusseted Bag, Quad Sealed Bag, Shaped Bag,etc. We can also provide wide range of zippers and other features to add even more value to the bags according to each client’s needs.

5

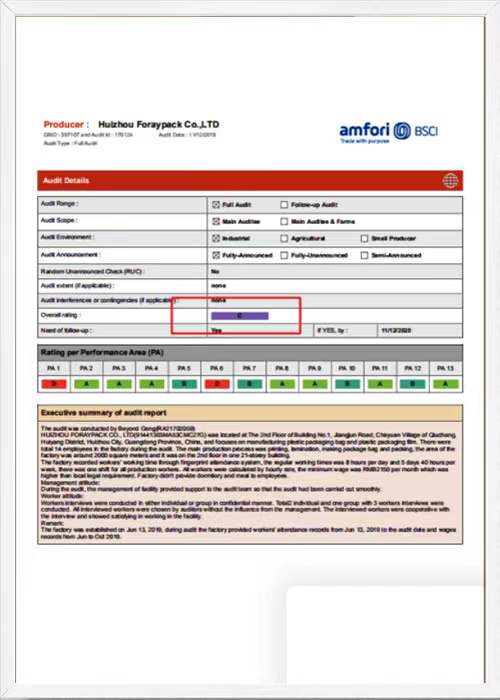

QA

It is a way of preventing mistakes and defects in manufactured products and avoiding problems when delivering products or services to customers! On a daily basis, our QA team work tight to deliver our clients safe and reliable products.

Of course, we accept third party QA if you need.